What is Nitronic Alloy?

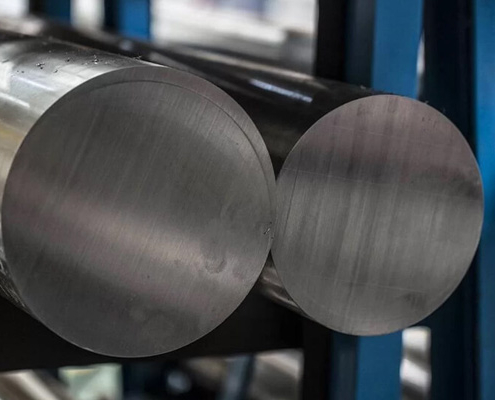

Nitronic is the trade name referring to an exact group of nitrogen-enhanced super duplex stainless steels. Nitronic alloys are used to create a wide range of components including fasteners, valves, and fittings. Nitronic alloys don’t rust in saltwater like other metals do, which makes them perfect for marine hardware and applications. These materials are also widely used in the pulp and paper, nuclear energy, and petroleum and chemical processing industries.

Nitronic is corrosion and heat-resistant austenitic stainless steel. It is widely used in marine, chemical processing, and petrochemical applications. The steel is resistant to pitting and crevice corrosion and has good resistance to intergranular corrosion. Nitronic has good mechanical properties and is tough and ductile. It can be cold-worked and welded.

What are the Nitronic 50, and 60 alloys and their differences?

Nitronic 50

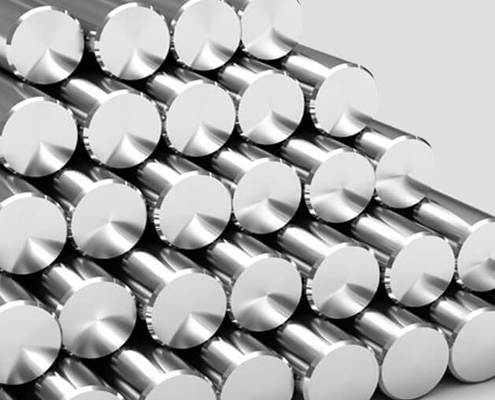

A premium austenitic stainless steel called Nitronic 50 offers greater corrosion resistance than stainless steel from the 300 or 400 series. This alloy is a great pick for high-risk applications like medical implants due to its strength, outstanding corrosion resistance, and low magnetic permeability. It also remains non-magnetic in cold environments, unlike other austenitic grades.

Common applications for Nitronic 50 include:

- Valves fittings, particularly stem due to the excellent alloy toughness

- Marine applications, include rod rigging using cold-drawn lengths, tie-downs, and fittings

- Pump shafts

- Sucker rods for oil rigs

- Fasteners

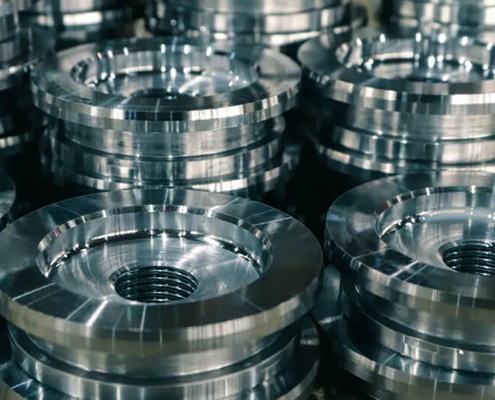

Nitronic 60

Nitronic 60 is specifically formulated to achieve excellent galling and wear resistance and is used in applications such as connectors. Nitronic 60 was designed to offer resistance to galling – a form of wear caused by adhesion between sliding surfaces and metal-to-metal wear.

https://www.besteelalloys.in/wp-content/uploads/2022/12/Nitronic-50-and-60-Suppliers-in-Chennai.jpg

400

500

besteel_login

https://www.besteelalloys.in/wp-content/uploads/2022/10/logo.png

besteel_login2022-12-19 07:23:362022-12-19 07:25:1117.4 PH Suppliers in Chennai

https://www.besteelalloys.in/wp-content/uploads/2022/12/Nitronic-50-and-60-Suppliers-in-Chennai.jpg

400

500

besteel_login

https://www.besteelalloys.in/wp-content/uploads/2022/10/logo.png

besteel_login2022-12-19 07:23:362022-12-19 07:25:1117.4 PH Suppliers in Chennai