What is 304L Stainless Steel, its Advantages & its Application?

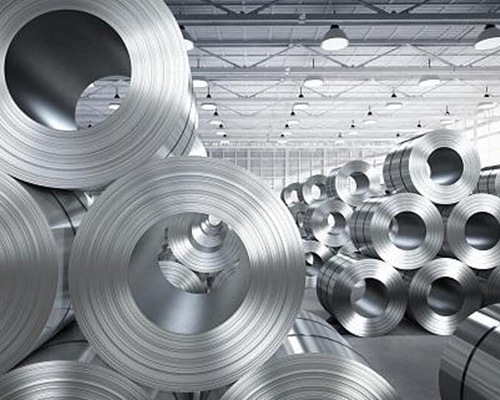

Stainless steel 304L is also known as stainless steel 1.4301 and 1.307 separately. Type 304 is the most versatile and widely used stainless steel. Even now, type 304 is still occasionally referred to by the old term 18/8, which comes from the nominal composition of 18% chromium and 8% nickel. An austenitic grade of stainless steel that can be severely deep drawn is type 304. Due to this characteristic, 304 is the most common grade utilized in products like sinks and saucepans.

Advantages Of Stainless Steel

Ease of manufacture almost all stainless steels can be easily formed by cutting, welding, hot and cold forming, and machining processes.

Mechanical Strength

Cold forming is used to strengthen the majority of stainless steel. As a result of the increased strength, material thicknesses can be reduced in designs, which significantly reduces part weight and cost. Heat treatments are able to give the material in some species a very high strength.

Appearance

Stainless steels are available in many different surface qualities. The appearance and quality of these surfaces can be easily maintained for a long time since they are easy to maintain.

Hygienic Feature

The easy cleanability of stainless steel makes these materials widely used in hospitals, kitchens, food, and pharmaceutical industries.

Long Life

Since stainless steels are durable and easy-to-maintain materials, they are economical materials considering the entire lifetime of the produced part.

Application:

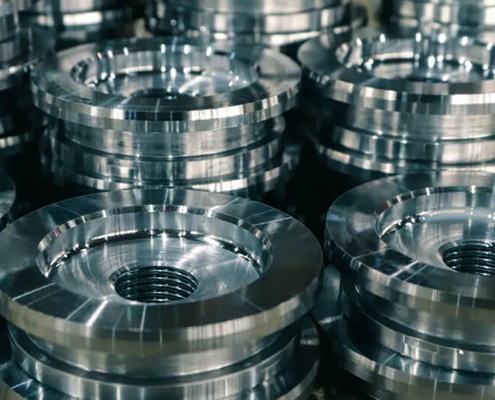

Alloy 304L Stainless Steel is used in a wide variety of home and commercial applications, including:

- Food processing equipment, particularly in beer brewing, milk processing, and winemaking

- Kitchen benches, sinks, troughs, equipment, and appliances

- Architectural trim and molding

- Automotive and aerospace structural use

- Construction material in large buildings

- Chemical containers, including for transport

- Heat exchangers

- Nuts, bolts, screws, and other fasteners in the marine environment

- Dyeing industry

- Woven or welded screens for mining, quarrying & water filtration

https://www.besteelalloys.in/wp-content/uploads/2022/12/Nitronic-50-and-60-Suppliers-in-Chennai.jpg

400

500

besteel_login

https://www.besteelalloys.in/wp-content/uploads/2022/10/logo.png

besteel_login2022-12-19 07:23:362022-12-19 07:25:1117.4 PH Suppliers in Chennai

https://www.besteelalloys.in/wp-content/uploads/2022/12/Nitronic-50-and-60-Suppliers-in-Chennai.jpg

400

500

besteel_login

https://www.besteelalloys.in/wp-content/uploads/2022/10/logo.png

besteel_login2022-12-19 07:23:362022-12-19 07:25:1117.4 PH Suppliers in Chennai